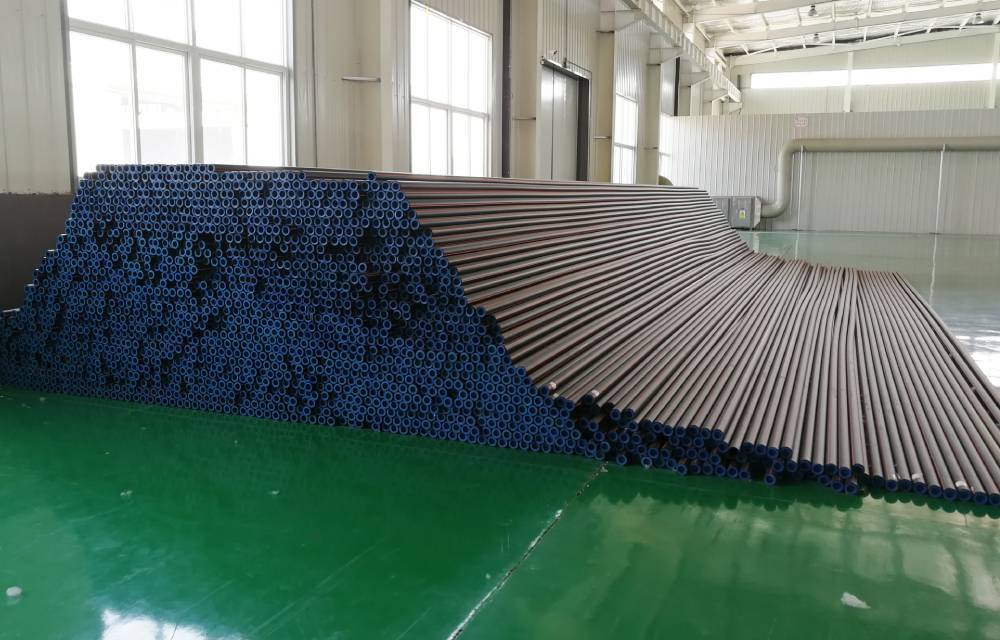

Producible Specifications:

DN20mm-DN400mm

Application Areas:

Urban Gas Transmission

Keywords:

PE100 gas pipe

Category:

Details Description

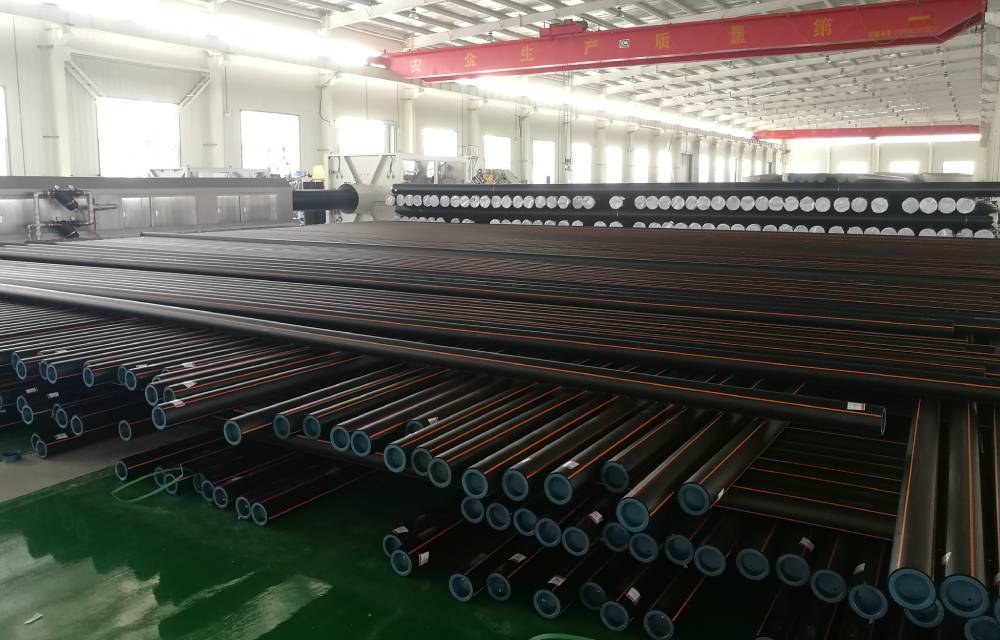

PE gas pipes are specialized pipelines for gas transmission made primarily from polyethylene (PE) resin. They feature corrosion resistance, high compressive strength, and good flexibility, and are widely used in urban gas and industrial gas supply fields.

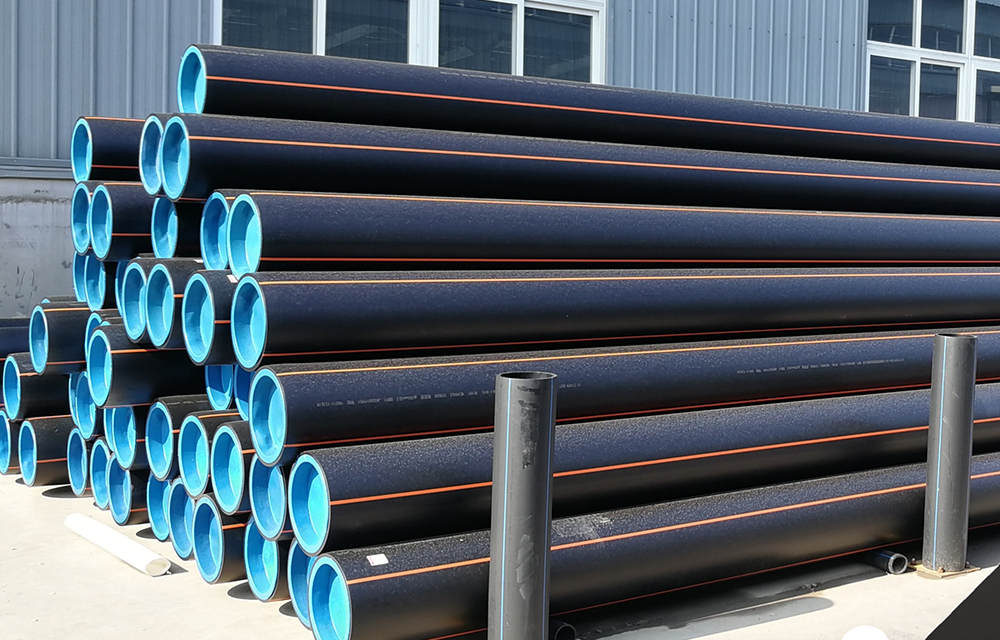

The trend in recent years has been to replace steel pipes with PE100 gas pipes. PE100 gas pipes offer high toughness, with an elongation at break generally ≥500%, and possess strong resistance to both rapid and slow crack growth. Statistics from the 1995 Hanshin Earthquake in Japan reportedly showed that regional gas supply systems using PE pipes remained largely intact.

PE100 gas pipes are the leading choice for modern gas distribution systems, offering superior strength, durability, and safety for residential, commercial, and industrial applications. Manufactured from high-density polyethylene (HDPE), these pipes are designed to meet the most demanding requirements of gas supply networks. Their exceptional resistance to corrosion, pressure, and environmental stress ensures the long-term reliability of the entire gas distribution system. With a growing demand for efficient and sustainable infrastructure, PE100 gas pipes are the ideal solution for secure and leak-proof gas transportation.

One of the most significant advantages of PE100 gas pipes is their resistance to corrosion and chemical degradation. Unlike traditional materials like steel or cast iron, PE100 pipes do not rust, rot, or corrode, even when exposed to harsh soil conditions or aggressive gases. This characteristic ensures the longevity and integrity of the gas distribution system, reducing maintenance costs and the risk of leaks. Additionally, the smooth inner surface of PE100 gas pipes minimizes friction and pressure loss, which enhances the overall efficiency of the gas transportation system.

PE100 gas pipes are engineered to withstand high-pressure applications, making them suitable for a wide range of gas supply needs, from small residential networks to large-scale industrial and municipal projects. These pipes can handle both low and high-pressure gas distribution, providing flexibility in design and ensuring consistent gas delivery over long distances. The robust nature of PE100 material ensures the pipes maintain their strength and performance, even in demanding operating environments. This makes PE100 gas pipes a reliable and cost-effective solution for gas transportation in any setting.

In addition to their technical benefits, PE100 gas pipes also offer easy installation and long-term maintenance advantages. The lightweight design of these pipes makes them easier to transport and handle during installation, saving time and reducing labor costs. The flexibility of PE100 allows for easy adaptation to complex pipeline layouts, ensuring a smooth and efficient installation process. Furthermore, PE100 gas pipes are highly resistant to UV radiation and other environmental factors, ensuring a reliable performance even in outdoor applications.

In conclusion, PE100 gas pipes are the gold standard for modern gas distribution systems. Their excellent mechanical properties, high-pressure resistance, and long-lasting performance make them the ideal choice for both new installations and upgrades of existing gas infrastructure. Whether you're building a residential pipeline or managing a large-scale industrial gas supply network, PE100 gas pipes provide the safety, reliability, and efficiency required to meet the highest industry standards.

Previous Page

Next Page

Previous Page

Next Page

Related Products

Urban main water supply network; seawater desalination; secondary water supply in residential communities; water distribution in mountainous and complex terrain areas; industrial fluid transportation (chemical plants, power plants, mines, etc.)

Urban main water supply network; seawater desalination; secondary water supply in residential communities; water distribution in mountainous and complex terrain areas; industrial fluid transportation (chemical plants, power plants, mines, etc.)

Central heating; hot spring delivery; geothermal heating; building hot and cold water systems

Seawater desalination; oil and gas field produced water oil removal and purification; advanced treatment of sewage plants and mine water; wastewater reuse in industrial parks; chemical cleaning and wastewater recovery in factories

Inquiry

We will contact you within one business day. Please pay attention to your email.